I remember visiting a blacksmith shop years ago and admiring the floor. Not long before that I had completed my shop building and wished I had thought about this idea.

This was a shop larger than mine which took on larger jobs than those I do. It was a forging and fabricating business. The floor of the main room where assembly was done was concrete. There was an exposed steel grid and the visible steel faces were about 3” in width. I think the grid may have been three or four foot squares. This permitted a large structure to be welded to the floor for assembly and cut off when finished. The grid was also a part of the welding current circuit.

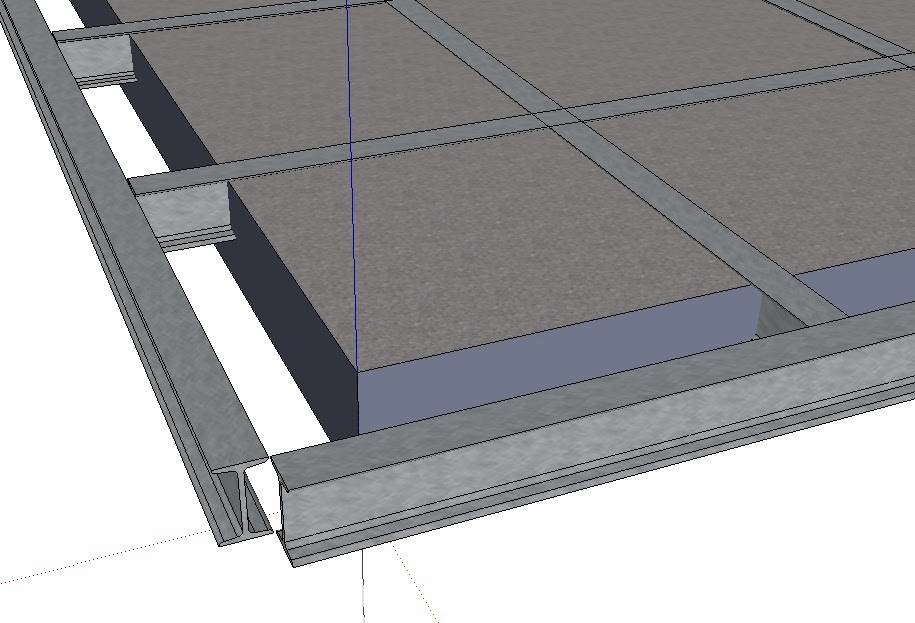

I think back to the day the floor of my shop was formed and ready for pouring over a standard rebar grid. In my mind I can remove the rebar and replace it with a grid of welded 3” I-beams, dead level, plumb and square. Pour, screed and leave the beam face exposed. In my shop just a 15’ x 15’ grid would be more than enough.

Possibly just welding some vertical steel posts to a standard rebar grid and later cutting them off flush could serve a similar purpose much less expensively.

The I-beam grid floor is a perfect example of the kind to thing I might lust for and don’t really need. But I think it might be just what someone with bigger plans might find useful. Also, rebar is cheap and I-beam is pricey so the whole shebang might really not be a good idea after all.

|

| 15' I-Beam Grid |

|

| Detail of exposed beam face |

|

| I-Beam extruded for illustration |

No comments:

Post a Comment