On May 16, 2001 I mentioned my round stock shear made by Don Nichols.

Don and Joyce stopped over on their way home from the ABANA conference in Rapid City and we had a nice visit. I asked if he minded if I wrote a post about this great tool which he makes from time to time and he said I could do it.

He said that his versions have some variations based on what is available as tool steel scrap. He usually selects 4140 which can be drilled and then oil quenched. I looked for web references about heat treating and found several. It sounds like heating to above magnetic and quenching in ATF or a light cooking oil would work. Heating the oil a little may help too.

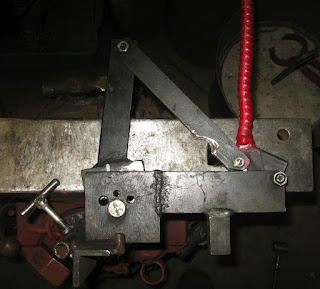

The shear design is mechanically a clever four-bar linkage. The length ratios produce a powerful force multiplication so cutting the round stock requires very little effort but I’ve never taken the time to do the math on it. I have set up my tool with an anvil tang and a vise tang, added a length stop and padded the handle with sash cord.

I’m on my second shear now only because a piece of 3/8” round 5160 coil spring got mixed up in the mild steel stock and broke a blade. I’m really careful not to water cool even mild steel which may later be cut. Water quenched 1020 or A36 may not dependably harden enough to make a decent tool but it can harden enough to ruin an edge tool or bandsaw blade.

No comments:

Post a Comment